What is Process Capability (Cpk)?

What is Process Capability (Cpk)?

Cpk is shorthand for the term “process capability index.” It is a statistical measure of process capability that engineers use as a tool to determine how accurately a target is met.

Why is Cpk such an important parameter with sealer heating technology?

Cpk is used throughout the sealing process as a way to measure how accurately and repeatably seals are being applied. Heat sealers apply temperature, pressure, and time to create seals of a specified, targeted seal strength. Cpk is used to determine how accurately that seal strength is reached and how consistently it is reached over time.

What type of industries are focused on Cpk?

Since Cpk is a statistical measure of process capability, it can have application in any industry where defined processes are used repeatedly. Cpk is particularly useful in packaging because it can be used to measure how accurately and repeatedly a sealing machine applies a seal.

Why type of medical products are packaged with pouch sealers and why is Cpk important in those packaging processes?

Pouch sealers are used to package high value medical products that need to be kept sterile. These products run the gamut from single-use, disposable medical devices, such as catheters and stents, to devices that ultimately become a permanent part of a patient’s anatomy, such as the components used for hip replacements and the screws and rods that can be used to repair bone fractures. Pouch sealers are also used to package certain surgical instruments, although in these cases, the instruments are cleaned, sterilized, and packaged in pouches more than once.

When packaging medical products that must remain sterile, it is critical to consider Cpk. That is because Cpk helps determine how accurately and repeatedly a heat sealer has applied the seal that will maintain sterility. It is vital to know that the packaging seal has been applied according to specifications; otherwise, there is little assurance that the product will remain sterile, and the lives of end users could be at risk.

What type of machines are used to seal medical device pouches?

Medical device pouches can be sealed in a variety of different ways, depending on the type of pouch material being used, the sealing temperatures needed, and other factors. Broadly speaking, these medical grade heat sealers are either constant heat sealers or impulse heat sealers.

Impulse heat sealers

The heating element in an impulse heat sealer is a very thin wire that can heat up and cool down quickly. It generates an “impulse” of heat, allowing the die to rapidly reach temperature and then cool down, all while under pressure. Impulse heat sealers are typically used for either the high temperature sealing or welding of mono-layer materials. They are usually not used for sealing pouches made from multi-layer materials because when the temperature fluctuates between heating and cooling every cycle, it is difficult to maintain accurate temperature control.

Constant heat sealers

A constant heat sealer has a heater embedded into its aluminum ceiling die. The operator sets this heater to a certain temperature and turns it on. After a few minutes, the heat is evenly distributed across the ceiling die, and the die will remain at this temperature until the sealer is turned off. Because they maintain one, consistent temperature, constant heat sealers are the easiest heat sealers to validate. They also provide the most stable, repeatable sealing process and require less ongoing maintenance than other types of sealers. Most of the seals used in sterile medical pouches are produced by constant heat sealers.

A continuous band or rotary band heat sealer is a type of constant heat sealer that uses opposing bands to carry pouches through the heat sealing process. The operator feeds the leading edge of the pouch into the sealer, where it is captured by the bands and pulled through to the section where heat is applied. The heat brings the materials to the melt point and seals them together, and then the bands continues to pull the pouch through the sealer to an unheated section where cooling occurs. The cooled pouch then emerges from the machine. Interestingly, a continuous band or a rotary band heat sealer offers the benefits of both constant and impulse heat. The actual pouch sealing is done with constant heat, which is a very stable temperature, but then the pouch is pulled along to an area where there is no heat, enabling it to cool under pressure.

What is the difference between a weld seal and a peelable seal?

Medical pouches are sealed using either a weld seal or a peelable seal. For a weld seal, the two layers of pouch material are annealed, or welded, together. This creates a seal that is quite strong. While a weld seal is optimal for certain applications, it can introduce problems when the pouch needs to be opened. At times, opening a weld seal can result in tearing the pouch, creating fibers or very small particles that could compromise the sterility of the product, the pouch, or the environment where the pouch is being opened. A peelable seal is different because it is strong enough to withstand handling and shipping, but not so strong that it presents problems when the pouch needs to be opened. As the name implies, a peelable seal can be easily peeled open. It must be tested for both strength and peelability, and then the heat sealer must be set for those parameters of temperature, pressure, and time. The sealing process must be very accurate and repeatable to ensure that each pouch maintains sterility and can be easily peeled open at the time of use.

What sealing parameter has the most impact on Cpk?

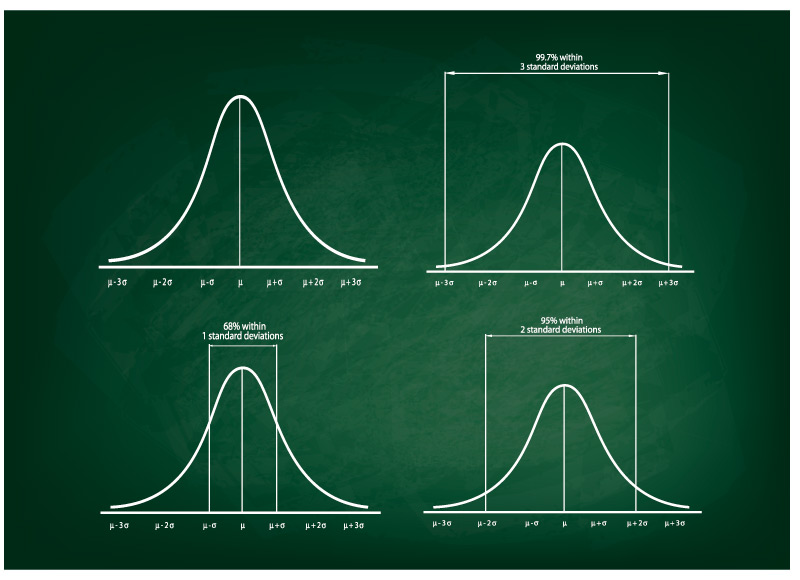

The sealing parameter that has the most impact on Cpk is heat, whether that is the temperature set point or the duration of time that that pouch is exposed to the heat. The temperature must be consistent and repeatable at the defined set point. Any variation widens the average and lowers the Cpk. Ideally, the Cpk is as high as it can be with a very tight average. That is why it is critical to reduce variation in all heat sealer set points, especially temperature. Temperature can be difficult to control because of fluctuations related to factors such as air movement, heat sinks, and pouch materials.

How do the upper and lower dies on a heat sealer vary with regard to heat loss and gain?

The upper die on a constant heat sealer is constantly battling heat loss. During the sealing cycle, each time a (heated) upper die makes contact with an (unheated) lower die, it loses some heat. That means it is essential for the upper die to have a very tight heating profile and constantly adjust to maintain temperature over time. By contrast, an unheated lower die will continually gain heat throughout a sealing run. That means, as the run progresses, the pouches toward the end of the run could be exposed to different sealing conditions than those at the start of the run. Differences like these can be accentuated by the speed and attention of the operators using the sealers. Using a heat sealer with a lower heated die that is fully controlled and alarmed can eliminate much of this variability and improve Cpk.

How can a heat sealer with a lower heated die help the integrity of the sealing process and improve Cpk?

Cpk improves as variables are eliminated. Adding temperature regulation to the lower die gives the operator control over yet another variable in the entire sealing process. Our pouch sealer with a lower heating die is becoming increasingly popular because customers are finding that having a controllable, heated lower die allows them to improve Cpk.

What are the factors that affect Cpk for medical pouch sealing?

Cpk for medical pouch sealing is affected by a wide variety of factors, ranging from how much temperature, time, and pressure is applied during the sealing process to which materials are used to create the pouch. In addition, Cpk can be affected by how the desired seal strength is initially determined and tested over time. After all, it is important that any seal strength testing is repeatable and accurate, as well. Weighing all of these different factors can be daunting. That is why it is so important to work closely with the manufacturer of your heat sealer. They can help you develop a full understanding of the heat sealing process and the most effective ways for you to improve Cpk.